MEW 735

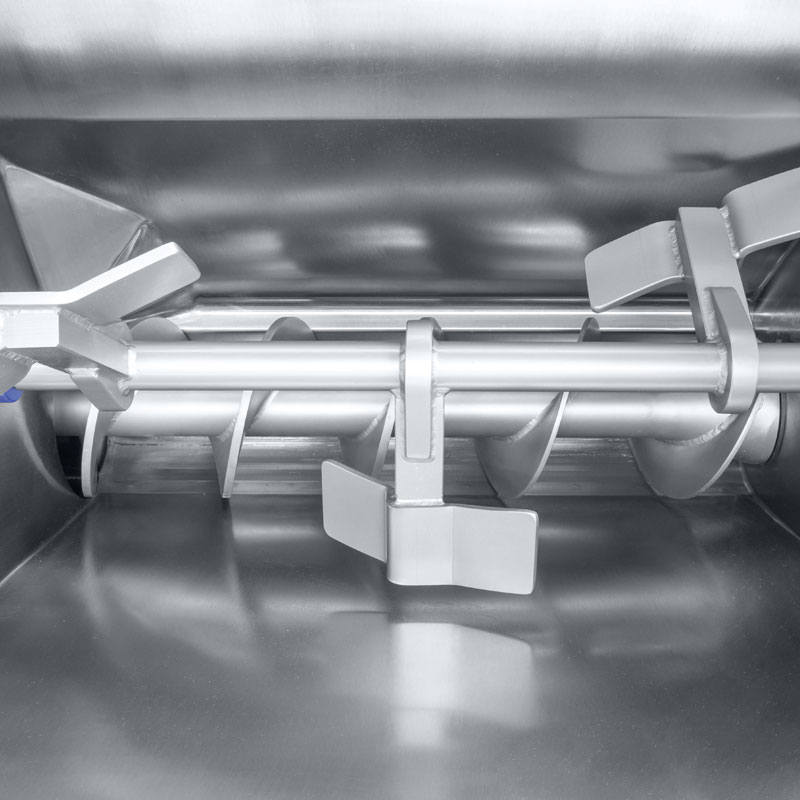

Angle mincer

Illustrations may contain special equipment.

MEW 735

MADO Angle mincers are continuously developed in a process of ongoing dialogue between our design engineers, specialist consultants and customers. As a result of these many years of development: Our customers have at their disposal a machine that is powerful and easy to maintain. For MADO, the focus is always on the customer’s end product > your product!

We use high quality raw materials and the latest, in-house production technology so that we can always guarantee a uniformly high standard of quality. With MADO angle mincers, the latest technology, the free-standing fully stainless steel housing and the hygienic design work together to ensure optimum production results at all times

Standard equipment:

- Machine, processing worm and feeding worm made of stainless steel

- Reverse mode

- Rinsing chambers for processing worm and feeding worm

- Hopper protected by an electrically locked cover

- Hopper protected by an electrically locked switching frame

- Stepless processing worm

- Self-regulating feeding worm

- Electrically locked step

- Electrically locked outlet guard

- Loading device for 200 litres meat trolleys

- Machine, processing worm and feeding worm made of stainless steel

- Reverse mode

- Rinsing chambers for processing worm and feeding worm

- Hopper protected by an electrically locked cover

- Hopper protected by an electrically locked switching frame

- Stepless processing worm

- Self-regulating feeding worm

- Electrically locked step

- Electrically locked outlet guard

- Loading device for 200 litres meat trolleys

Options / accessories:

- More powerful drive (11 – 20 kW)

- Stepless mixer shaft (variant M/BM)

- Separating system lateral or central, manually operated

- Lateral separator pneumatically operated, incl. control system

- “DuoSepart” central and lateral, manually operated

- “DuoSepart” central and lateral, pneumatically operated, incl. control system

- Cleaning and transport trolley

- Hydraulic loading device for 200 litres meat trolleys

- More powerful drive (11 – 20 kW)

- Stepless mixer shaft (variant M/BM)

- Separating system lateral or central, manually operated

- Lateral separator pneumatically operated, incl. control system

- “DuoSepart” central and lateral, manually operated

- “DuoSepart” central and lateral, pneumatically operated, incl. control system

- Cleaning and transport trolley

- Hydraulic loading device for 200 litres meat trolleys

All Angle mincers

Inquiry & Contact